WellCAM 360 Gallery

In the examples below, you will see applications where WellCAM 360 has provided invaluable benefit to the end user, enabling them to make informed decisions based on the visual log and detailed visual analysis whilst running above a primary intervention tool such as brushing, PLT, milling or cutting tools.

WellCAM 360 delivers stunning clarity of GLV

WellCAM 360 was used to investigate a GLV at around 10,000ft.

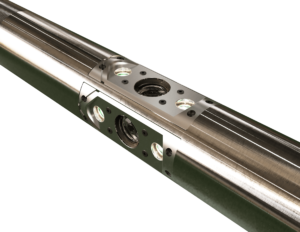

The WellCAM 360 is a world-first, unique 4-array camera that provides a seamless 360 degree panorama of features in the wellbore. It has a power and telemetry feed-through so can be run above primary intervention tools to provide unrivalled visual analytics.

In this video, the feed from one of the cameras with the GLV in clear view is highlighted to demonstrate the high level of detail and quality achievable from this camera.

WellCAM 360 – visual logging PLT to help North Sea operator with water cut-off in a gas well

Challenge

A North Sea operator had a high water cut gas production well with a gravel packed lower completion. The operator wanted to run a production loggin tool (PLT) to conform where in the completion the water breakthrough was taking place. Due to the high water cut, the operator was concerned that the PLT would not be able to accurately pinpoint the areas where water break through was occurring, as such the operator decided to run WellCAM 360 in combination with the PLT. Optimizing the intervention program to incorporate more than one operation in one or more of the intervention runs had the potential to save time, money and CO2 emissions.

Solution

The operator and Vision iO prepared a work program which included both an onshore SIT and the offshore operation. The SIT involved running WellCAM 360 integrated into a BHA with the PLT. Due to compatibility issues discovered during the SIT between the communication systems used by the WellCAM 360 and PLT, the decision was taken to run the WellCAM 360 in memory/feed through mode, as there was not enough time to solve the issue before the intervention was scheduled.

Result

The data from the PLT did not give any indication of the zones where water break through had been taking place. After retrieving the data from the WellCAM 360 the operator was able to accurately pinpoint the areas where water break though was taking place. The operator subsequently injected a resin plug which sealed off the water producing zones. After just one day the well showed zero water production and an increase in gas production.

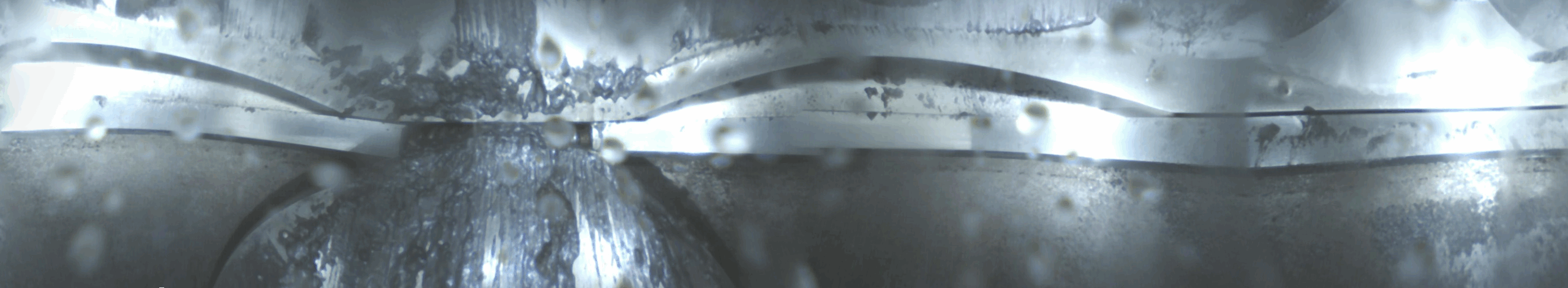

The video above shows a short clip clearly identifying water flowing through the sand screens. This is an example of many points of water entry, which allowed the resin plug to be set in the correct position to seal off the water production zones.

WellCAM 360 – world first integrated camera and brush clean up

The clip above shows a summary of the process of identifying and cleaning the well bore. The judering in the first section is the BHA jarring, demonstrating the rubustness of the WellCAM 360.

Before brushing: showing the scale/debris on the sidewall;

During brushing: the particualte can be seen in suspension;

After brushing: even with lens slightly obscured by debris, the effectiveness of the clean up is conclusive.

Challenge

AkerBP, a North Sea operator, had an installed TRSSV in a well that was not holding pressure. The operator needed a visual analysis of the TRSSV to assist in diagnosing the issue. Once the issue was identified and remedial action taken, the operator needed to confirm the effectiveness of the remedial action. Optimizing the intervention program to incorporate more than one operation in one or more of the intervention runs had the potential to save time, money and CO2 emissions.

Solution

AkerBP and Vision iO prepared a work program which included both an onshore SIT and the offshore operation. The SIT involved running WellCAM 360 integrated into a BHA with the mechanical brushing tool in a new TRSSV to establish datum baseline visual logs. Camera measurements would be taken for later comparison with the images captured during the offshore operation to identify any issues observed and to allow efficient remedial work if required. Any additional data retrieved from the offshore intervention would be evaluated.

Result

Images were captured of the TRSSV operating where the flapper was observed fully closing. The upper edge flow tube was observed consistently cycling to its expected upper limit. Frack proppants were observed within the mechanism of the flapper and proppants were seen in orifices in the camera at surface. A thick flow of frack proppants and debris was observed when the flapper was opened.

Mineral deposits were observed in the upper completion above the TRSSV, and multiple (+100) jarring operations were required to get the BHA to the required location and perform the brushing operation.

During the brushing, removed debris was seen in suspension and solution. WellCAM 360 was used to confirm that the tubing was clean. Had a standard downhole camera been used, at least one extra slickline run would have been required.

WellCAM 360 captures lower and upper edge of functioning flowtube

The clip above demonstrates the 360 degree panoramic view of the profile of the lower edge of the flowtube as it is cycled whilst the WellCAM360 is in the wellbore. The camera itself imtentionally prevents the flapper from fully closing in order to view the internal mechanism and the profile around the flapper.

The clip above shows the 360 degree panoramic view of the upper edge of the flow tube moving upwards as it completes its cycle to close the TRSV.

360 degree panorama of flapper in its open position

The image below shows the 360 degree panoramic view of the flapper valce in its open position.

Vision WellCAM 360 whilst brushing – an animated explanation

This is an animation simulating the effects of the brush on the scale and debris within a wellbore and the benefot of running WellCAM 360 above the brush in thedeployed BHA. It is a simulation of the actual job detailed above, utilised in the Norwegian sector of the North Sea.

The primary function of hte job was to inspect the internal mechanism of a TRSV which was cleaned by mechanical brushing. However, a secondary benefit was clearly gained as the wellbore above the TRSV underwent cleaning, with visual confirmation provided by WellCAM 360.

The visual confirmation provided by WellCAM 360 removed the need for additional well intervention thius vastly reducing time, cost and significantly reducing CO2 emissions.